EAF waste dust recycling tehnology

Laboratory and pilot research work, 2006 - 2008 Laboratory faze:

Laboratory faze:Diferent size ( Ø 4 – 15 mm) of the self-reduce pelletes are produced in laboratory granulate drum with diferent fix carbon content (15%, 20%, 25% CFix ). Reduction proces was realized used an laboratory furnace, where the test it was mainteined in different stationary time (20 – 60 min) in three temperature levels: 1100°C, 1200°C and 1300°C.

The self-reduced pelletes characteristics, with 40-90% metalizing degree, are: 50% Fe, max. 1,5% Zn, B2 - 1,3 and strength max. 60 kg/pellete.

Pilot faze:

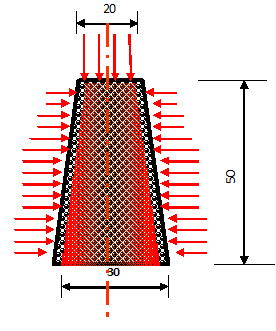

Pilot reduction room

Pilot reduction roomThree bicameral reduction reactors was produced for pilot instalation.

The upper rooms are comunicate with inferior room only by two laterally gase rooms. Reduction gas is outlet from reactor in inferior part. Upper room has five trapesium section pellete layers which have a summary dry pelletes capacity about 6 kg. Reactor dimentions are 300 x 900 mm adopted for tunnel furnace dimentions.

When reduction reactor cross the heating zone of the tunnel furnace, under burners flame the pellete layers are heating from three directions. Stationary time of the reactor in high temperature zone is adjust by furnace van speed. Burner flame strike upper side of the reactor, being a hot screen, and heat the self reducing pelletes layer without direct contact.

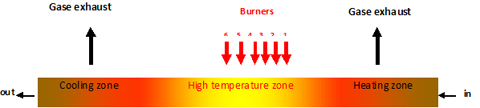

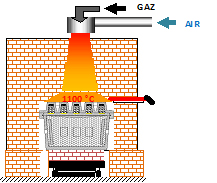

Principal technological unit of the recycling line is reduction furnace. It has three processing zones, drying, layer heating and reduction zone. Eight burned rooms produce the thermical energy necessary for reduction proces, that will be delivered to self reduced pellete layer by radiate trasferring.

Principal technological unit of the recycling line is reduction furnace. It has three processing zones, drying, layer heating and reduction zone. Eight burned rooms produce the thermical energy necessary for reduction proces, that will be delivered to self reduced pellete layer by radiate trasferring.Burned gas is the energy source for two first furnace zones, and a part of this energy will be recovered by thermal recovering unit.

Estimated processing cost is 117,6 Euro/ton EAF recycled dust and methane gas consumution 190 Nm3/ton reduce pellete. Calculated furnace efficiency is 62%.